How Data Analytics Can Improve Airworthiness Management

As we all know, airworthiness management is a crucial aspect of aviation safety, as it ensures that aircraft are maintained and operated safely and reliably. In recent years, advancements in technology and the increasing amount of data generated by aircraft have opened up new opportunities for data analytics to improve airworthiness management.

One of the main benefits of using data analytics in airworthiness management is that it allows for a more proactive approach to aircraft maintenance. Traditionally, airworthiness management relied on manual inspections and checks, which could only identify problems after they had already occurred. With data analytics, it is possible to monitor the performance of aircraft systems in real time and detect potential issues before they cause problems.

The following are some of the ways in which data analytics can improve airworthiness management:

Predictive Maintenance:

Data analytics can be used to monitor the performance of aircraft systems in real-time, detect anomalies, and predict potential problems before they occur. Predictive maintenance enables airlines to schedule maintenance activities at the right time, reducing downtime and maintenance costs.

Flight Data Monitoring:

The data generated by an aircraft during a flight, such as speed, altitude, and engine performance, can be used to identify any deviations from normal operating conditions. This information can then be used to optimize maintenance activities and improve the overall airworthiness of the aircraft.

Maintenance Performance Analysis:

Data analytics can be used to analyze maintenance activities and identify areas where improvements can be made. This can include analyzing the efficiency of maintenance processes, identifying the root cause of maintenance problems, and reducing the frequency of repetitive maintenance activities.

Inventory Management:

Data analytics can be used to optimize inventory management, reducing the risk of stock shortages and reducing costs associated with overstocking. By analyzing data on spare parts usage, airlines can optimize their spare parts inventory, reducing the time and costs associated with searching for parts when they are needed.

Cost Management:

Data analytics can be used to analyze the cost of airworthiness management, identifying areas where costs can be reduced. For example, data analytics can be used to analyze the cost of maintenance activities, the cost of spare parts, and the cost of downtime.

Safety Management:

Data analytics can play a crucial role in improving safety in aviation by identifying potential safety risks. Airlines can identify trends and develop strategies to prevent future incidents by analyzing data on aircraft incidents and accidents.

Data Quality and Standardization

However, before airlines can really benefit from data analytics we need to focus on one rather important point here namely data quality and data standardization!

Probably you are familiar with the term garbage in garbage out – you cannot drive value from data and make the right decisions on flawed data. Hence, before starting with data analytics you need to work on your data.

But the question is, where to start? If you have been using your MRO/M&E system for let’s say 10 years and have a fleet of around 50 aircraft tons of terabytes of data reside in the MRO/M&E system and every day more data is added to the system. It can be like facing the basement in your house or your storage where you have added stuff every day for the last 10 years and now is the time to clean it up, organize, and label everything so that you know what you have and can find it back easily when you need it.

Having your data organized, cleansed, labeled, identifying, and filling the gaps is needed for data analytics, your digitization strategy, and airworthiness compliance.

There Are Always Multiple Reasons For ‘Poor’ Data Quality. However, These Are The Top 3:

During the introduction of an MRO/M&E system, data was never cleaned properly, implicating problems from the beginning as the source was never correct as well. Or after using a system for quite some years regular data checks do not take place.

Employees are aware that procedures are not followed properly in the chain, and many workarounds have been applied in the course of the history of the MRO/M&E system making it unreliable or, at best, giving slight concerns to the user base.

Multiple systems are used in parallel which will have, for sure, synchronization issues at some point in time and create doubt among the company about which system should be used and, more importantly, which system is correct.

Some of these problems look seemingly innocent and things are often put away as insignificant compared to the sheer size of modern datasets. But be aware, down the line, small issues can and will have an exponential impact as the dataset grows, eventually leading to things such as full inventory audits to verify your stock and the value it represents, doing labour intensive dirty fingerprint checks because of high doubts of the system status. Or, in the worst-case scenario, keeping an aircraft AOG as there might be discovered that critical items are overdue making the aircraft instantly non-airworthy, potentially shortening its economic life. We’ve seen real-life materialization of all these examples during our work in the field.

Ask Yourself

We would like to invite you to ask yourself the following questions:

1. How long ago was the implementation of your current MRO software?

a) Less than 5 years ago

b) More than 5 years ago

2. Do you conduct regular data scans/checks, at least once a year?

a) Yes

b) No

3. How often do you find yourself double-checking something from your own system?

a) Never

b) Quite often

4. Do you avoid double entries of data?

a) Yes

b) No

5. Are people doing multiple things in the system outside of their original scope/function

a) No

b) Yes

6. How many component serial number readouts per aircraft per year do you have due to doubts in the system?

a) Less than 10

b) More than 10

If you have mainly chosen answer a, then you are on the right track. Keep up the good work! With this level of data quality, you might want to start looking into enabling more value from your aircraft data set by looking into advanced analytics and predictive analytics.

If you mainly have chosen answer b, it might be time to start addressing some of the core issues. Of course, you still operate within allowable boundaries of airworthiness management, however, as your aircraft data will further grow so will the potential risks of the impact of this aircraft data quality on critical airworthiness items.

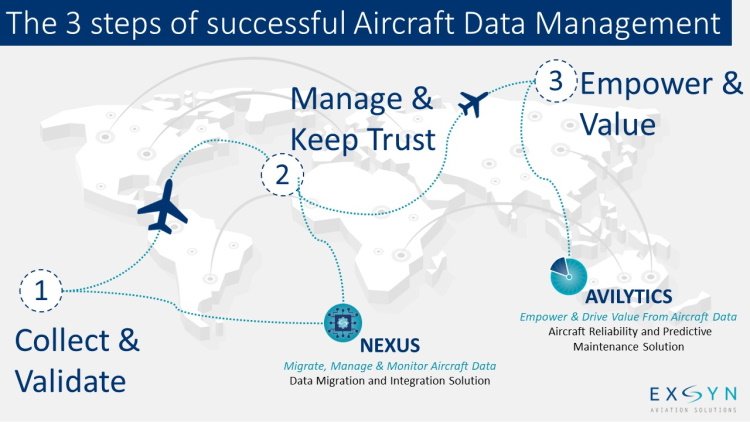

Data analytics can significantly improve airworthiness management in aviation by enabling a more proactive approach to aircraft maintenance, reducing maintenance costs, optimizing inventory management, and improving safety. As technology continues to advance, we can expect to see even more innovative applications of data analytics in airworthiness management, helping to ensure the continued safety and reliability of aircraft. BUT please do not forget about data quality and standardization, you need to focus on it first in order to be able to drive value from your data. Have also a look at our 3 steps to successful aircraft data management: