Are you ready for predictive maintenance?

Over the last several years data generated by aircraft has increased exponentially thru introduction of new onboard equipment that allows for the so-called connected aircraft. In the wake of this data growth OEM’s and airlines alike the interest in data analytics and predictive maintenance has risen alike. According to the MRO survey 2017 by Oliver Wyman (When Growth Outpaces Capacity) 77% of respondents want to implement predictive analytics in the coming three years. The MRO survey 2017 by Aircraft IT confirms this trend as most respondents answered that next to paperless maintenance predictive analytics will play a major role in the development the upcoming years. According to the latest MRO Survey by Oliver Wyman (2018 – Tackling Industry Disruption) predictive maintenance is seen among airlines as a means to combat rising material costs and improve labour productivity and shortage in the future.

Let’s start at the beginning what predictive maintenance?

Predictive maintenance involves the use of information such as sensor data, and statistical modeling to calculate what the condition of systems and components could be at a given moment in time to predict maintenance needs in advance. It helps airlines to determine when maintenance should be performed.

What is the aim of Predictive Maintenance?

Within aviation maintenance and engineering the aim of predictive maintenance is first to predict when a component failure might occur, and secondly, to prevent the occurrence of the failure by performing maintenance. Monitoring for future failure allows maintenance to be planned before the failure occurs, thus reducing unscheduled removals and avoiding AOG.

Benefits of applying predictive maintenance

Improve operations:

forecast inventory

manage resources

Reduce costs:

minimizing the time, the equipment is being maintained

minimizing the production hours lost to maintenance, and

minimizing the cost of spare parts and supplies.

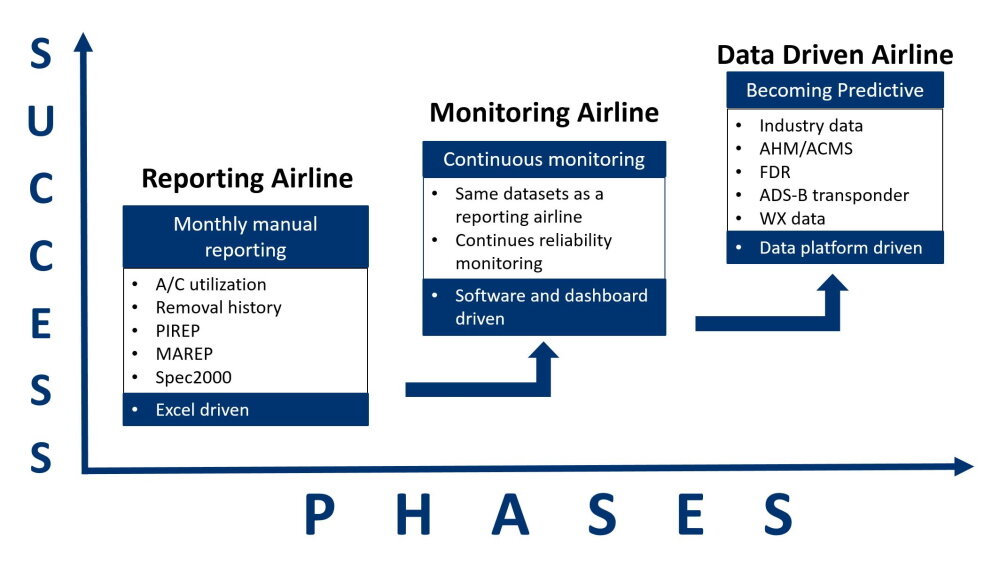

Based on years of research EXSYN has identified three main phases, where the last defines the status of being able to become predictive:

Success stages Predictive Maintenance in Aircraft Maintenance

Let’s have a closer look at the three types of airline:

The reporting airline

The reporting airline is characterized by producing monthly reliability reports, drawing from manual work of retrieving the various information such as aircraft utilization, Pilot reports, Maintenance findings and component removals and then consolidate this data into Excel.

This typically is a very manual labour-intensive process and puts the reporting airline in a situation that they are able to produce the reports on monthly bases but not action on these reports.

The monitoring airline

The monitoring airline, stands 1 level higher on the adoption success scale of becoming predictive. This type of airline typically already moved away from excel reports and uses an analytical tool and mostly also dashboards. This allows the airline to act more quickly on rising issues and monitor the fleet than rather reporting the status of their fleet.

However, it still draws on the same set of data, the SPEC2000 chapter 11 reliability data. Which ultimately prevents the airline of adopting any predictive maintenance models as data sets are to limit to become reliable enough for operational usage.

The data driven airline

The data driven airline, has the highest level of adoption success for predictive maintenance models. It used all character traits of the monitoring airline but has recognized the need of having access to larger sets of data beyond its own airline data, such as industry reliability data, Flight Data Recorder information, weather data as well as ADS-B transponder data. Ultimately the data driven airline implements a data driven platform in its organization that provides information to its operational units such as maintenance operations control to make informed decisions in day-of-operation itself.

The question is where are you currently standing, are you ready for predictive maintenance?

Here are several questions you should to ask yourself:

Has your airline an integrated MRO software?

Is your MRO software less than 8 years old?

Is the MRO software updated at least once a year?

Does your airline have interfaces built between various sources of information within your IT setup? (i.e. Records, Maintenance, Engineering, Inventory, Finance & Resource, Flight Operations data)

Does your airline conduct data audits to secure that data is up-to-date?

Does your airline have a high data integrity/quality?

Do you cross-reference and update data against sources and revisions?

Does your airline use a software solution (not EXCEL) to perform reliability analysis?

Does your airline need to manipulate or correct data every time before the airline reliability report is published?

Does your airline have access to weather data?

Does your fleet use onboard data systems such as AHM or ACARS?

Is your airline's flight department willing to share Flight Data Recorder information with other departments?

Is your airline willing to share technical and operational data with other airlines that operate the same aircraft type(s)?

What now?

Have you answered the first four questions with yes?

Great you have entered the first stage of the process and are a reporting airline. This means you are able to produce analytical insight into your data, however it is mostly requiring some significant effort Typically your reliability engineer(s) spend a lot of time on producing reports and do not have sufficient time for further analysis. Also, as data is still dispersed thru various departments, time is spent on consolidation and alignment of data.

In case “no” was the answer to any of the first 3 questions, chances are high that your current data and system landscape is not complete enough to start implementing anything close to predictive maintenance or predictive analytics. Due to the lack of data or reduced data quality any outcome would be below required thresholds for adequate prediction models. The first next step to undertake is to perform a full holistic data scan on your MRO data to identify the required actions to proceed.

Have you answered all first nice questions with yes?

You have entered the stage of being a monitoring airline. Based on our experience we know that many airlines are in-between the first and second stages. Often EXCEL is still present in many airlines but there is some sort of platform or software in place that allows for direct analysis without data corrections. The highest risk in this stage is that it seems compelling to start looking at predictive analytics as lots of data is available, however, albeit available it might still not be enough for proper predictions.

In case “no” was the answer to either questions 4, 5, or 6, your first port of call will be your data quality. You have a suitable infrastructure in place, but not enough controls yet to ensure a proper level of data quality.

Have you answered all 13 questions with yes?

Congratulations, you are ready for the successful implementation of predictive models within your airline. You can start by using the Avilytics AOG Risk Monitor. Click here to request a demo now!

In case your answer to one of the last 4 questions is “no” you’re missing a vital or multiple ingredient(s) for successful and reliable predictive models. Starting working on predictive models with one of these questions still on no will set you up for a failed project and potentially high sunk costs as results will always look promising enough to continue justifying the allocation of time, resources, and funds. However, a reliable prediction cannot be obtained without these datasets missing.

How EXSYN can help

EXSYN's team of aircraft data and aviation experts utilize a proven framework and methodology for adoption of predictive analytics in aviation. It has been applied to numerous fleets and aircraft and includes:

EXSYN’s pre-build Avilytics environment of analysis modules, widgets, formulas and algorithms on a wide range of ATA chapters and components

Workshops to identify the specific maintenance complaints to be monitored for each fleet operated by your airline

Implementation of identified complaints per aircraft type and registration into the Avilytics environment. Including data mining, validation and user interface design.

Native integration of the Avilytics modules in your own platform or hosting in the myEXSYN.com digital environment in case your airline does not have a data warehouse yet

Training of identified user groups

Adoption workshops to support successful day-to-day usage of the predictive analytical techniques and business models

Machine Learning to identify future potential maintenance complaints to be monitored

Ongoing software maintenance support for modules implemented